Temperature Regulated Coal Small Oil Chemistry Commercial Centrifuge for Used Cooking Oil

Overview Temperature Regulated Coal Small Oil Chemistry Commercial Centrifuge for Used Cooking Oil Product introduction

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | WLL1200 |

| Installation | Vertical |

| Centrifuge Type | Horizontal Spiral Centrifuge |

| Distillation Equipment Type | Essential Oil Distillation Equipment |

| Extraction Tower Type | Vibration Plate Tower |

| Pressure | High Pressure |

| Condition | New |

| Transport Package | Standard Export Package |

| Specification | according to product size |

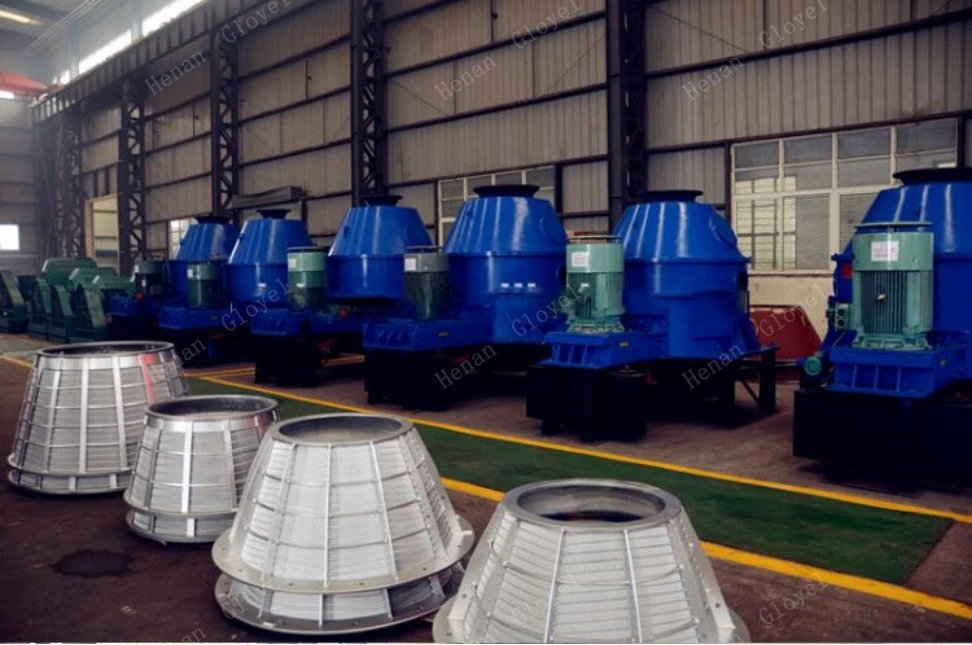

| Trademark | GLOYEL |

| Origin | Henan |

| Production Capacity | 100set/Month |

Product Description

Temperature Regulated Coal Small Oil Chemistry Commercial Centrifuge for Used Cooking Oil Product introductionVertical centrifuge

| Model | LL700 | LL900 | LL1000 | LL1200 | LL1400 |

| Feed moisture (%) | ≤30 | ≤30 | ≤30 | ≤30 | ≤30 |

| Feeding granularity (mm) | ≤25 | ≤25 | ≤25 | ≤25 | ≤25 |

| Product external moisture (%) | 6~12 | 6~12 | 6~12 | 6~12 | ≤13 |

| Processing capacity (t/h) | 40-50 | 60~100 | 100-150 | 140~200 | 200~250 |

| Screen large end diameter (mm) | 720 | 930 | 1050 | 1200 | 1400 |

| Screen mesh (mm) | 0.3/0.35/0.5 | ||||

| Screen speed (r/min) | 670 | 587 | 559 | 534 | 498 |

| Main motor power (kw) | 22 | 37/45 | 45/55 | 55/75 | 90 |

| Lubrication motor power (kw) | 0.75 | 0.75 | 0.75 | 1.1 | 1.1 |

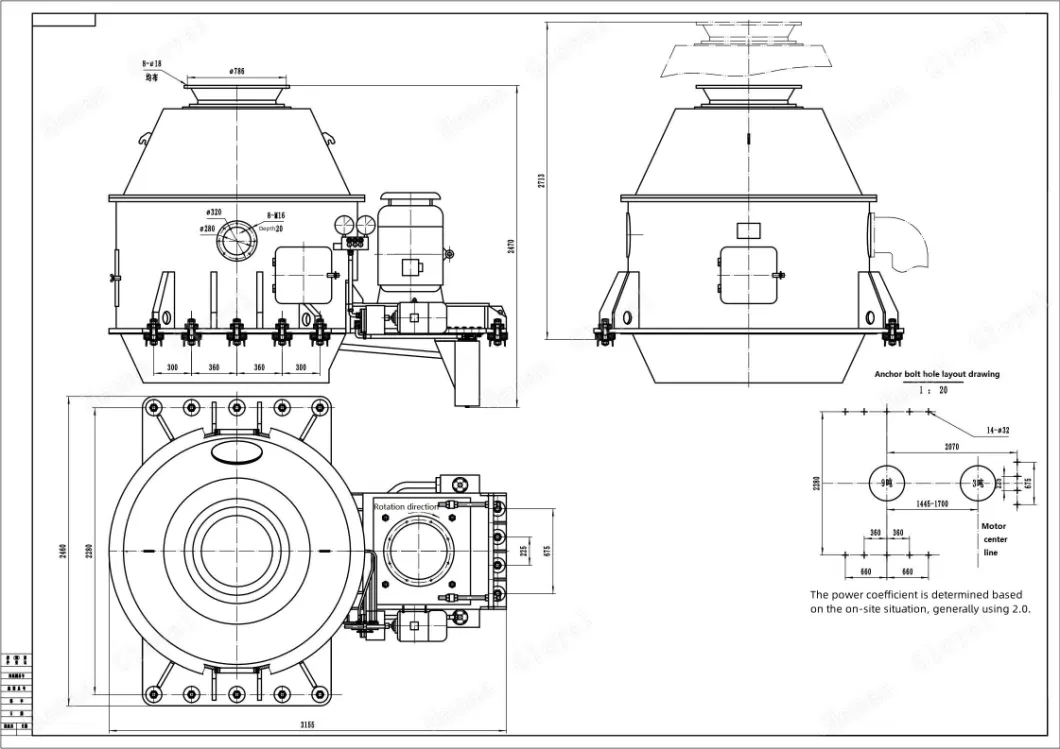

| Dimensions (mm) | 2275*1740*1820 | 2740*2030*2240 | 3000*2250*2362 | 3200*2500*2600 | 3255*2310*2476 |

| Machine weight (kg) | 2465 | 4713 | 5753 | 8000 | 9000 |

Simple structure, reliable operation, strong adaptability, and good dehydration effect;

Vulnerable parts are protected by high wear-resistant materials and have a long service life;

The gears are processed with ultra precision machinery, resulting in low equipment noise;

There are many types of models that can meet the needs of various specifications of coal preparation plants.

Working principle

LL series vertical centrifuge is a dehydration equipment that utilizes mechanical rotation to generate centrifugal force and achieve solid-liquid mixture separation. After the wet material enters the centrifuge through the feeding port, the material is accelerated by the rotating distribution cone and quickly moves towards the space between the screen bar and the rotor body. Under the centrifugal force, the smaller particles of the material cling tightly to the screen surface, while the liquid and some materials with particle sizes less than 0.5 millimeters are thrown out of the screen bar through the material gap and screen bar gap. The larger particles of the material quickly slide down the spiral scraper and enter the discharge port under the gravitational centrifugal force, The fine materials attached to the screen surface are discharged from the centrifuge through the action of a scraper, while the liquid and fine materials thrown out by the screen bar enter the water tank and are discharged through a drainage pipe, thereby achieving solid-liquid separation.

Horizontal scrape centrifuge

| Model | Screen mesh(mm) | Processing capacity(r/min) | Feeding granularity(mm) | Product moisture(%) | Main motor power(kw) | Oil pump motor power(kw) | Overall dimensions(mm) | Weight(kg) |

| WLL1000 | 0.375 | 50~85 | 0.15~3 | 12~16 | 75 | 0.75 | 2300*2400*2010 | 4500 |

| WLL1200 | 0.375 | 60~110 | 0.15~3 | 12~16 | 75 | 0.75 | 2348*2634*2230 | 4900 |

Reliable operation, strong adaptability, and low noise.

Differential overload protection.

The vulnerable parts are protected with high wear-resistant materials, with a long service life.

Large processing capacity and low product moisture.

Simple structure, convenient maintenance, horizontal operation, reducing the height requirements of the factory building.

Working principle

The WLL series coal slurry scraper discharge centrifuge is a universal horizontal scraper discharge centrifuge. The material passes through the feeding pipe to the bottom of the scraper and screen bar, and is tightly attached to the screen surface under centrifugal force. Due to the speed difference between the scraper and screen bar, the material layer evenly moves towards the large end of the screen bar under the action of the scraper. The dehydrated material is thrown out of the large end of the screen bar and falls into the discharge port at the bottom of the machine casing. The water in the material is thrown around the shell through the material layer and screen gap under the action of centrifugal force, and flows towards the discharge port along the inner wall.Application Range

Payment

GLOYEL accept different kinds of payment,such as T/T, L/C, Western Union, Money Gram.

Shipment

GLOYEL has established long-term and reliable cooperation with professional packing and shipping company.

1.How to buy your interested products?

You can provide us the slurry source, and slurry processing output, flow rate and ground area, material requirements about your project (More details, please contact us).

2.How to pay?

L/C or T/T are acceptable.Usually, 50% payment in advance, 50% payment before delivery.

3.What is the delivery time?

It depends on order quantities. Generally speaking, the delivery time will be within 2months.

4.How to pack the products?

We use standard export package.If you have special package requirements, we will pack as you required, but the fees will be paid by customers.

5.How to install after the equipment arriving destination?

We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you.

6.How long is the validity?

The validity is 12 months after installation.

Related Products

-

![Shadowless Operation Theater Lights Double Head Surgical Lamp]()

Shadowless Operation Theater Lights Double Head Surgical Lamp

-

![LED Operating Light Lampara Cielitica Scialitic Surgical Lamp Operation Theater Light Lampara Quirofano Medicas Surgery Lamp]()

LED Operating Light Lampara Cielitica Scialitic Surgical Lamp Operation Theater Light Lampara Quirofano Medicas Surgery Lamp

-

![Hot Selling Height Adjustable Hydraulic Electric Pet Medical Table]()

Hot Selling Height Adjustable Hydraulic Electric Pet Medical Table

-

![Dog Washing Machine with Dryer Grooming Salon Bath in Stainless Steel]()

Dog Washing Machine with Dryer Grooming Salon Bath in Stainless Steel